Product Description

Agricultural Motorcycle Auto Track Trailer Front Wheel Hub Car Motorcycle Spare Parts 6310 Deep Groove Ball Bearing with high precision

Bearing parameters:

| CHROME STEEL* | Dimensions in mm unless otherwise specified |

||||||

| Bore | O.D. | Width | Open Bearing | Shielded Bearing | Sealed Bearing | Basic Load Ratings | |

| KN | |||||||

| HNS | HNS | HNS | dynamic | static | |||

| Reference | Reference | Reference | C | Co | |||

| 20 | 42 | 12 | 6004 | 6004ZZ | 6004-2RS | 7.22 | 4.46 |

| 47 | 14 | 6204 | 6204ZZ | 6204-2RS | 12.7 | 6.5 | |

| 52 | 15 | 6304 | 6304ZZ | 6304-2RS | 15.9 | 7.8 | |

| 25 | 47 | 12 | 6005 | 6005ZZ | 6005-2RS | 10.1 | 5.85 |

| 52 | 15 | 6205 | 6205ZZ | 6205-2RS | 14 | 7.8 | |

| 62 | 17 | 6305 | 6305ZZ | 6305-2RS | 22.5 | 11.6 | |

| 80 | 21 | 6405 | 6405ZZ | 6405-2RS | 36.1 | 19.4 | |

| 30 | 55 | 13 | 6006 | 6006ZZ | 6006-2RS | 10.2 | 6.91 |

| 62 | 16 | 6206 | 6206ZZ | 6206-2RS | 19.5 | 11.2 | |

| 72 | 19 | 6306 | 6306ZZ | 6306-2RS | 28.1 | 16 | |

| 90 | 23 | 6406 | 6406ZZ | 6406-2RS | 43.4 | 23.9 | |

| 35 | 62 | 14 | 6007 | 6007ZZ | 6007-2RS | 16 | 10.3 |

| 72 | 17 | 6207 | 6207ZZ | 6207-2RS | 25.5 | 15.3 | |

| 80 | 21 | 6307 | 6307ZZ | 6307-2RS | 33.2 | 19 | |

| 100 | 25 | 6407 | 6407ZZ | 6407-2RS | 55 | 31 | |

| 40 | 68 | 15 | 6008 | 6008ZZ | 6008-2RS | 13 | 11.5 |

| 80 | 18 | 6208 | 6208ZZ | 6208-2RS | 29.8 | 18 | |

| 90 | 23 | 6308 | 6308ZZ | 6308-2RS | 39.8 | 23.3 | |

| 110 | 27 | 6408 | 6408ZZ | 6408-2RS | 65.5 | 37.5 | |

| 45 | 75 | 16 | 6009 | 6009ZZ | 6009-2RS | 21 | 14.9 |

| 85 | 19 | 6209 | 6209ZZ | 6209-2RS | 32.2 | 21 | |

| 100 | 25 | 6309 | 6309ZZ | 6309-2RS | 51.1 | 30.5 | |

| 120 | 29 | 6409 | 6409ZZ | 6409-2RS | 77.5 | 45.5 | |

| 50 | 80 | 16 | 6571 | 6571ZZ | 6571-2RS | 22 | 16.2 |

| 90 | 20 | 6210 | 6210ZZ | 6210-2RS | 34 | 22.5 | |

| 110 | 27 | 6310 | 6310ZZ | 6310-2RS | 59.9 | 36.9 | |

| 130 | 31 | 6410 | 6410ZZ | 6410-2RS | 92.2 | 55.2 | |

| 55 | 90 | 18 | 6011 | 6011ZZ | 6011-2RS | 30.4 | 22 |

| 100 | 21 | 6211 | 6211ZZ | 6211-2RS | 43.3 | 28.1 | |

| 120 | 29 | 6311 | 6311ZZ | 6311-2RS | 71.5 | 44.6 | |

| 140 | 33 | 6411 | 6411ZZ | 6411-2RS | 100 | 62.5 | |

| 60 | 95 | 18 | 6012 | 6012ZZ | 6012-2RS | 30.7 | 22.7 |

| 110 | 22 | 6212 | 6212ZZ | 6212-2RS | 46.1 | 31.5 | |

| 130 | 31 | 6312 | 6312ZZ | 6312-2RS | 79.4 | 50.4 | |

| 150 | 35 | 6412 | 6412ZZ | 6412-2RS | 109 | 70 | |

| 65 | 100 | 18 | 6013 | 6013ZZ | 6013-2RS | 32.1 | 24.9 |

| 120 | 23 | 6213 | 6213ZZ | 6213-2RS | 54.2 | 39.3 | |

| 140 | 33 | 6313 | 6313ZZ | 6313-2RS | 89.5 | 59.7 | |

| 160 | 37 | 6413 | 6413ZZ | 6413-2RS | 118 | 78.5 | |

| 70 | 110 | 20 | 6014 | 6014ZZ | 6014-2RS | 38.6 | 30.6 |

| 125 | 24 | 6214 | 6214ZZ | 6214-2RS | 58.9 | 43.6 | |

| 150 | 35 | 6314 | 6314ZZ | 6314-2RS | 101 | 66 | |

| 180 | 42 | 6414 | 6414ZZ | 6414-2RS | 140 | 99.5 | |

| 75 | 115 | 20 | 6015 | 6015ZZ | 6015-2RS | 31 | 33.1 |

| 130 | 25 | 6215 | 6215ZZ | 6215-2RS | 64.3 | 47.5 | |

| 160 | 37 | 6315 | 6315ZZ | 6315-2RS | 111 | 74.2 | |

| 190 | 45 | 6415 | 6415ZZ | 6415-2RS | 154 | 115 | |

| 80 | 125 | 22 | 6016 | 6016ZZ | 6016-2RS | 47.5 | 39.8 |

| 140 | 26 | 6216 | 6216ZZ | 6216-2RS | 68.1 | 53.3 | |

| 170 | 39 | 6316 | 6316ZZ | 6316-2RS | 120 | 83.9 | |

| 200 | 48 | 6416 | 6416ZZ | 6416-2RS | 163 | 125 | |

| 85 | 130 | 22 | 6017 | 6017ZZ | 6017-2RS | 50.8 | 42.8 |

| 150 | 28 | 6217 | 6217ZZ | 6217-2RS | 83.2 | 64 | |

| 180 | 41 | 6317 | 6317ZZ | 6317-2RS | 132 | 96.5 | |

| 210 | 52 | 6417 | 6417ZZ | 6417-2RS | 175 | 138 | |

| 90 | 140 | 24 | 6018 | 6018ZZ | 6018-2RS | 58 | 49.8 |

| 160 | 30 | 6218 | 6218ZZ | 6218-2RS | 92.7 | 71.3 | |

| 190 | 43 | 6318 | 6318ZZ | 6318-2RS | 145 | 108 | |

| 225 | 54 | 6418 | 6418ZZ | 6418-2RS | 192 | 158 | |

| 95 | 145 | 24 | 6019 | 6019ZZ | 6019-2RS | 57.8 | 50 |

| 170 | 32 | 6219 | 6219ZZ | 6219-2RS | 105 | 79.1 | |

| 200 | 45 | 6319 | 6319ZZ | 6319-2RS | 157 | 122 | |

| 100 | 150 | 24 | 6571 | 6571ZZ | 6571-2RS | 64.5 | 56.2 |

| 180 | 34 | 6220 | 6220ZZ | 6220-2RS | 118 | 88.4 | |

| 215 | 47 | 6320 | 6320ZZ | 6320-2RS | 173 | 140 | |

| 105 | 160 | 26 | 6571 | 6571ZZ | 6571-2RS | 71.8 | 63.2 |

| 190 | 36 | 6221 | 6221ZZ | 6221-2RS | 126 | 98.8 | |

| 225 | 49 | 6321 | 6321ZZ | 6321-2RS | 173 | 145 | |

| 110 | 170 | 28 | 6571 | 6571ZZ | 6571-2RS | 81.9 | 72.9 |

| 200 | 38 | 6222 | 6222ZZ | 6222-2RS | 136 | 112 | |

| 240 | 50 | 6322 | 6322ZZ | 6322-2RS | 193 | 171 | |

| 120 | 180 | 28 | 6571 | 6571ZZ | 6571-2RS | 88.7 | 79.7 |

| 215 | 40 | 6224 | 6224ZZ | 6224-2RS | 139 | 112 | |

| 260 | 55 | 6324 | 6324ZZ | 6324-2RS | 217 | 196 | |

| 130 | 200 | 33 | 6026 | 6026ZZ | 6026-2RS | 105 | 96.8 |

| 230 | 40 | 6226 | 6226ZZ | 6226-2RS | 148 | 125 | |

| 280 | 58 | 6326 | 6326ZZ | 6326-2RS | 218 | 205 | |

| 140 | 210 | 33 | 6571 | 6571ZZ | 6571-2RS | 116 | 108 |

| 250 | 42 | 6228 | 6228ZZ | 6228-2RS | 179 | 167 | |

| 300 | 62 | 6328 | 6328ZZ | 6328-2RS | 275 | 272 | |

| 150 | 225 | 35 | 6030 | 6030ZZ | 6030-2RS | 132 | 125 |

| 270 | 45 | 6230 | 6230ZZ | 6230-2RS | 190 | 183 | |

| 160 | 240 | 38 | 6032 | 6032ZZ | 6032-2RS | 145 | 138 |

| 290 | 48 | 6232 | 6232ZZ | 6232-2RS | 215 | 218 | |

About Deep Groove Ball Cearing

- 6000 Series – Extra Light Ball Bearings – Ideal for limited space applications

- 6200 Series – Light Series Ball Bearings – Balanced between space and load capacity

- 6300 Series – Medium Series Ball Bearings – Ideal for heavier load capacity applications

Deep groove ball bearing component:

Rich bearings in stock:

OEM is available:

Application

Package:

A. Plastic paper + kraft paper + outer carton + Nylon bag

B. Tube package + outer carton + Nylon bag

C. Single box + outer carton + pallets

D. According to your requirement

For more information, contact us directly pls.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Contact Angle: | 0 |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the maintenance and lubrication requirements for track bearings?

Maintenance and lubrication are essential aspects of ensuring the optimal performance and longevity of track bearings. Proper maintenance practices and appropriate lubrication help minimize wear, reduce friction, prevent corrosion, and extend the service life of the bearings. Here’s an explanation of the maintenance and lubrication requirements for track bearings:

Maintenance Requirements:

- Cleanliness: It is crucial to maintain a clean operating environment for track bearings. Regularly remove dirt, dust, and debris from the track and bearing surfaces to prevent contamination, which can lead to premature wear and damage.

- Inspection: Periodically inspect the track bearings for signs of wear, damage, or misalignment. Check for excessive play, noise, or roughness during operation. If any issues are detected, take appropriate measures such as bearing replacement or realignment to ensure optimal performance.

- Tightening and Fasteners: Check the tightness of fasteners, such as bolts or screws, that secure the track bearings. Loose fasteners can lead to misalignment or instability. Ensure that all fasteners are properly tightened according to the manufacturer’s specifications.

- Track Alignment: Proper track alignment is crucial for smooth and efficient operation of track bearings. Regularly check the alignment of the track or guide rails and make necessary adjustments to maintain proper alignment, minimizing excessive loads and wear on the bearings.

- Load Limits: Adhere to the specified load limits for the track bearings. Exceeding the recommended load capacity can cause premature wear and failure. Consider the dynamic and static load ratings of the bearings to ensure they are not subjected to excessive loads that can compromise their performance.

Lubrication Requirements:

- Proper Lubricant Selection: Select the appropriate lubricant based on the operating conditions, such as temperature, load, and speed. Consult the manufacturer’s recommendations or seek expert advice to ensure the lubricant’s compatibility with the track bearings and the specific application.

- Regular Lubrication: Follow a regular lubrication schedule as recommended by the manufacturer. This may involve applying lubricant at specified intervals or based on the operating hours. Adequate lubrication helps minimize friction, reduce wear, and maintain proper functioning of the track bearings.

- Correct Lubrication Method: Apply the lubricant using the appropriate method, whether it’s manual greasing, automatic lubrication systems, or specialized lubrication techniques. Ensure that the lubricant reaches all necessary contact points and provides sufficient coverage to the bearing surfaces.

- Monitoring and Replenishment: Monitor the lubricant levels regularly and replenish as needed. In some cases, track bearings may have built-in lubrication systems that require periodic refilling or maintenance. Keep track of the lubricant condition and replace it when it becomes contaminated or degraded.

- Environmental Considerations: Consider the operating environment when selecting the lubricant. Extreme temperatures, exposure to moisture, or the presence of chemicals or contaminants may require special lubricants that can withstand these conditions and provide effective protection and lubrication.

It is important to consult the manufacturer’s guidelines and recommendations specific to the track bearings being used. Following the recommended maintenance and lubrication practices ensures optimal performance, reduces the risk of premature failure, and maximizes the overall lifespan of the track bearings.

How do track bearings enhance the overall efficiency and functionality of linear motion systems?

Track bearings play a crucial role in enhancing the overall efficiency and functionality of linear motion systems. They offer several benefits that contribute to improved performance, increased reliability, and enhanced functionality. Here’s a detailed explanation:

- Reduced Friction: Track bearings are designed to minimize friction between moving components, allowing for smoother and more efficient linear motion. By reducing friction, they help to optimize the efficiency of the system, reducing energy consumption and minimizing wear on the components.

- Precision and Stability: Track bearings provide precise guidance and stability to the linear motion system. They ensure accurate and repeatable motion along the intended path, allowing for precise positioning and control. This is particularly important in applications that require high accuracy, such as CNC machines, robotics, and automated assembly lines.

- Load Distribution: Track bearings distribute the load evenly along their length, allowing for efficient load transfer and reducing the concentration of forces on specific components. This helps to prevent excessive wear, deformation, and premature failure of the system, improving overall reliability and longevity.

- Handling Heavy Loads: Track bearings are specifically designed to handle heavy loads in linear motion systems. They offer high load capacities and robust construction, enabling them to support and move heavy objects with ease. This capability is essential in industries such as material handling, construction, and transportation.

- Smooth and Quiet Operation: Track bearings are engineered to provide smooth and quiet operation, minimizing noise and vibrations in the linear motion system. This is especially important in applications where noise reduction and comfort are critical, such as in medical equipment, office automation, and consumer electronics.

- Versatility and Adaptability: Track bearings come in various designs, sizes, and configurations to accommodate different linear motion system requirements. They can be easily integrated into existing systems or customized to fit specific applications. This versatility allows for greater flexibility and adaptability in designing and implementing linear motion solutions.

- Maintenance and Serviceability: Track bearings are designed for ease of maintenance and serviceability. They often feature removable components, such as seals or shields, that allow for inspection, cleaning, and lubrication. This simplifies maintenance tasks and reduces downtime, contributing to improved overall system efficiency and uptime.

By incorporating track bearings into linear motion systems, industries can benefit from increased efficiency, improved performance, and enhanced functionality. Whether it’s achieving precise positioning, handling heavy loads, reducing friction, or ensuring smooth operation, track bearings play a vital role in optimizing the overall efficiency and functionality of linear motion systems.

Can you explain the different types of track bearings used in industrial and mechanical systems?

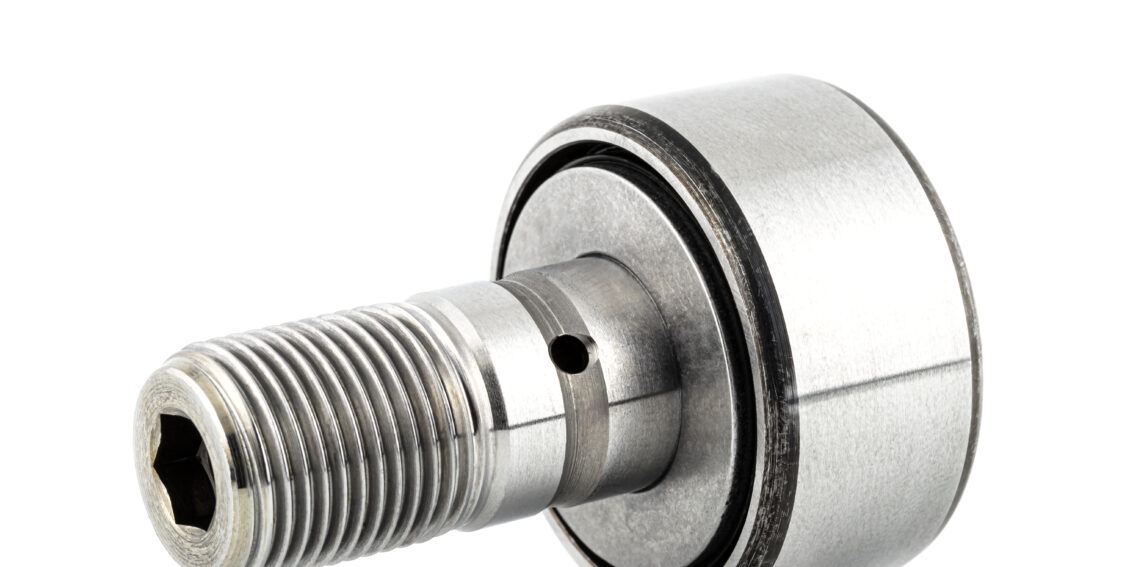

Track bearings, also known as track rollers or track follower bearings, come in various types to suit different industrial and mechanical system requirements. Let’s explore the different types of track bearings commonly used in these applications:

- Yoke Type Track Rollers: Yoke type track rollers are a popular type of track bearing characterized by their thick outer rings. They are designed to handle high radial loads and moderate axial loads. Yoke type track rollers feature an inner ring with a stud for mounting on a shaft or stud. They are widely used in applications such as conveyors, cam mechanisms, material handling systems, and agricultural machinery.

- Stud Type Track Rollers: Stud type track rollers are similar to yoke type track rollers but lack an inner ring. Instead, they have a stud that serves as the mounting component. Stud type track rollers are suitable for applications with limited space or where the outer ring can be directly mounted onto a mating surface. They are commonly used in applications such as cam mechanisms, indexing equipment, and tensioning systems.

- Cam Followers: Cam followers, also known as cam bearings or track followers, are track bearings designed specifically for cam-driven systems. They have a stud or shaft for mounting and a built-in roller or needle bearing. Cam followers follow the profile of a cam, converting the rotary motion of the cam into linear or oscillating motion. They are used in applications such as printing presses, packaging machinery, textile machinery, and automotive engines.

- Guiding Track Rollers: Guiding track rollers are track bearings designed to provide precise and guided linear motion. They feature a thick outer ring with a track or guide surface. Guiding track rollers are commonly used in material handling systems, conveyor systems, and automated machinery to facilitate smooth and controlled movement along a track or guide rail.

- V-Groove Track Rollers: V-groove track rollers have a specialized V-shaped groove on the outer ring. This groove allows the rollers to run on V-shaped tracks or rails, providing accurate alignment and guidance. V-groove track rollers are used in applications such as track systems, sliding gates, and linear motion guides.

- Flanged Track Rollers: Flanged track rollers feature an additional flange on the outer ring. The flange helps in axial guidance and prevents the track roller from shifting or tilting under axial loads. Flanged track rollers are commonly used in applications such as cam mechanisms, linear motion systems, and conveyor systems.

- Idler Track Rollers: Idler track rollers are non-powered track rollers used to support and guide conveyor belts, chains, or other moving components. They are typically used in material handling systems, conveyor systems, and packaging machinery.

These different types of track bearings offer versatility and flexibility in industrial and mechanical systems. Depending on the specific application requirements, engineers and designers can select the most suitable type of track bearing to ensure smooth motion, reliable operation, and efficient load support. The choice of track bearing type depends on factors such as load capacity, space constraints, track configuration, and environmental conditions.

editor by CX 2024-05-17

China Hot selling Agricultural Motorcycle Auto Track Trailer Front Wheel Hub Unit Car Motorcycle Spare Parts 6301 6004 6203 6205 6310 Deep Groove Ball Bearing with high quality

Product Description

Product Description

Company Profile

ZheJiang CZPT Bearing Co., Ltd. is affiliated to ZheJiang Kaidi Bearing Group – a specialized manufacturer of kinds of bearings for about 20 years.

Our company is specialized in producing Deep Groove Ball Bearings, Tapered Roller Bearings, Spherical Roller Bearings and Special Bearings in accordance with Customers’ designs.Our bearings has been widely applied into agricultural equipments, home appliances, power equipments, machine tools, automotives and engineering machinery, etc.

Our Products

ZheJiang CZPT Bearing Co., Ltd. is a specialized manufacturer of ball bearings for about 20 years. Our main products include:

1, Miniature Bearings: like 608, 609, 625, 626, 693, 695, etc;

2, Deep Groove Ball Bearings: like 6000, 6200, 6300, 6800, 6900, 16000 Series;

3,Non-Standard Bearings: U grooved bearings, V grooved bearings, double grooved bearings, bearing rollers with or without plastic injection. 4,Pillow Block Bearing: UCP/ UCF/ UCFL;

5,Tapered Roller Bearings

6,Linear Motion Bearings

Processing Process

we have manufacture bearing more than 20 years, and can produce different style of bearings. Our factory starts production from raw materials. We have a 20-person R&D team and launch a new product every 5 days. We have more than 600 people to produce bearing team, we produce products, the price is the most competitive in China.

Packaging & Shipping

Our Activities

FAQ

|

1.Q:Do you know the Detail Size for the Bearing ? 2.Q: This Size of Bearing is common parts? 3.Q:Are you a factory or a Trade Company for Bearing ? 4.Q:How many the MOQ of the Bearing? 5.Q:Could you supply free sample of bearing for our test? 6.Q:Could you accept OEM and customize? 7.Q:Do you have stocks? |

Contact Us

Jane

ZheJiang CZPT Bearing Co., Ltd.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 15° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Thrust Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 0.05/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does proper installation and alignment impact the performance and longevity of track bearings?

Proper installation and alignment play a critical role in the performance and longevity of track bearings. Correct installation ensures that the bearings are positioned and secured accurately, while proper alignment ensures that the load is distributed evenly and the bearings operate smoothly. Here’s an explanation of how proper installation and alignment impact the performance and longevity of track bearings:

Installation Impact:

- Load Distribution: Proper installation ensures that the track bearings are aligned and positioned correctly, allowing for even load distribution. When bearings are installed incorrectly, the load may be unevenly distributed, leading to excessive wear on certain parts of the bearings and reduced overall performance.

- Stability and Rigidity: Accurate installation provides stability and rigidity to the track bearings. Properly secured bearings minimize the risk of movement or vibration during operation, which can cause additional stress, premature wear, and potential damage to the bearings and surrounding components.

- Reduction of Misalignment: Correct installation minimizes the chances of misalignment between the track bearings and the track or guide rails. Misalignment can lead to uneven loading, increased friction, and accelerated wear and tear on the bearings. Proper alignment reduces these issues, ensuring smooth and efficient operation.

- Prevention of Contamination: During installation, it is important to take precautions to prevent contamination of the track bearings. Proper handling techniques, cleanliness, and the use of appropriate tools or protective measures help avoid introducing dirt, dust, or debris that can compromise the bearing’s performance and longevity.

Alignment Impact:

- Reduced Friction and Wear: Proper alignment of track bearings helps minimize friction and wear. When bearings are misaligned, excessive forces and irregular motion can occur, leading to increased friction and accelerated wear. Proper alignment ensures that the bearings operate within their intended design parameters, reducing friction and promoting longevity.

- Optimal Load Distribution: Correct alignment ensures that the load is distributed evenly across the track bearings. This prevents excessive stress on specific areas of the bearings, reducing the risk of premature failure and extending their service life. Optimal load distribution also contributes to smoother operation and improved overall performance.

- Minimized Noise and Vibration: Proper alignment helps minimize noise and vibration during operation. Misaligned track bearings can result in irregular motion, leading to unwanted noise and vibration that can affect the performance, comfort, and efficiency of the machinery or equipment. Proper alignment promotes smoother and quieter operation.

- Improved Efficiency: When track bearings are correctly aligned, the machinery or equipment experiences reduced resistance and improved efficiency. Misalignment can result in energy losses, increased power consumption, and decreased overall efficiency. Proper alignment ensures optimal power transfer and minimizes energy wastage.

It is important to follow the manufacturer’s guidelines and recommendations for the specific track bearings being installed. Proper installation techniques, including accurate positioning, secure fastening, and appropriate alignment, contribute to the optimal performance, reliability, and longevity of track bearings in various applications.

Can track bearings withstand harsh environments or exposure to contaminants?

Track bearings are designed to operate in a wide range of environments, including harsh conditions and exposure to contaminants. However, the ability of track bearings to withstand such environments depends on their specific design, materials, and protective measures. Here’s a detailed explanation:

Many track bearings are engineered with features that enhance their resistance to harsh environments and contaminants. These features may include:

- Sealing and Shielding: Some track bearings are equipped with seals or shields that provide a physical barrier against contaminants such as dirt, dust, water, and debris. These seals or shields help prevent the entry of contaminants into the bearing’s internal components, reducing the risk of damage and premature wear.

- Corrosion Resistance: Track bearings intended for use in corrosive environments are often constructed from materials that offer high corrosion resistance. Stainless steel, for example, is commonly used due to its ability to withstand exposure to moisture, chemicals, and other corrosive substances.

- Specialized Coatings: Some track bearings may feature specialized coatings or surface treatments that provide additional protection against contaminants and harsh conditions. These coatings can enhance the bearing’s resistance to corrosion, abrasion, and chemical exposure.

- High-Temperature Capability: Certain track bearings are designed to withstand high-temperature environments. They are typically constructed using heat-resistant materials and lubricants that can maintain their structural integrity and performance even under extreme heat.

- Environmental Sealing: In applications where track bearings are exposed to extreme conditions, such as underwater or in highly dusty environments, special environmental sealing measures may be employed. These measures can include the use of advanced sealing technologies or the encapsulation of the bearings within protective housings.

While track bearings are designed to withstand harsh environments and exposure to contaminants, it is important to note that their performance and longevity can still be affected over time. Regular maintenance, including cleaning, inspection, and lubrication, is crucial to ensure proper functioning and to mitigate the impact of contaminants on the bearings.

It is recommended to consult the manufacturer’s specifications and guidelines for the track bearings being used in a specific application. Manufacturers often provide information on the environmental ratings and limits of their bearings, helping users determine the suitability of the bearings for particular harsh environments or exposure to contaminants.

By selecting track bearings with appropriate features, materials, and protection, and by implementing proper maintenance practices, it is possible to enhance the bearings’ ability to withstand harsh environments and exposure to contaminants, thereby maximizing their performance and longevity.

What are the components of a track bearing assembly and their functions?

A track bearing assembly consists of several components that work together to facilitate smooth and controlled motion along a track or guide rail. Let’s explore the components of a typical track bearing assembly and their functions:

- Outer Ring: The outer ring is the outermost component of a track bearing assembly. It provides structural support and houses the rolling elements. The outer ring is designed with a track or guide surface that interfaces with the track or rail, allowing the bearing to move along the desired path.

- Inner Ring: The inner ring is located inside the outer ring and provides a mounting surface for the bearing assembly. It may have a stud or shaft for attaching the bearing to the application. The inner ring helps in aligning and positioning the bearing assembly.

- Rolling Elements: The rolling elements are the components that enable smooth rolling motion between the inner and outer rings. In track bearings, the rolling elements are typically in the form of rollers or needles. They are designed to minimize friction and distribute the load evenly along the track surface.

- Cage: The cage, also known as a retainer, is a component that holds the rolling elements in position and maintains proper spacing between them. The cage prevents the rolling elements from contacting each other, reducing friction and wear. It also helps in guiding the rolling elements during operation.

- Seals or Shields: Track bearings often incorporate seals or shields to protect the internal components from contaminants such as dirt, dust, and moisture. Seals provide a physical barrier between the bearing and the external environment, while shields offer partial protection while allowing some lubrication to reach the rolling elements.

- Lubrication: Proper lubrication is crucial for the smooth operation and longevity of track bearings. Lubrication reduces friction, dissipates heat, and prevents wear between the rolling elements and raceways. Lubricants can be applied through grease fittings or oil ports, ensuring that the rolling elements roll smoothly along the track surface.

- Mounting Hardware: Depending on the specific design and application requirements, track bearing assemblies may include mounting hardware such as studs, bolts, or fasteners. These components are used to securely attach the bearing assembly to the application, ensuring proper alignment and stability.

By combining these components, a track bearing assembly provides reliable and controlled motion along a track or guide rail. The outer and inner rings, along with the rolling elements and cage, enable smooth rolling motion, while seals or shields protect the internal components from contaminants. Proper lubrication and mounting hardware ensure optimal performance and longevity of the track bearing assembly.

editor by CX 2024-02-04

China wholesaler Sample Availabl Original Deep Groove Ball Bearing 6200 6201 6202 6203 6204 6205 6309 6902 Zz 2RS C3 R3 Auto Bearings for CZPT CZPT CZPT CZPT CZPT bearing driver

Product Description

Product Description

NSK CZPT CZPT CZPT CZPT Original Brand Bearing Tapered Roller Bearing Deep Groove Ball Bearing Wheel Hub Bearing Cylindrical Roller Bearing for Auto Parts

I. PRODUCT INFO.

HQA BEARING offers the most extensive line of tapered roller bearings in the world. Tapered roller bearings consist of 4 interdependent components: the cone (inner ring), the cup (outer ring), the tapered rollers (rolling elements) and the cage (roller retainer). Tapered roller bearings are uniquely designed to manage both thrust and radial loads between a rotating and non-rotating member. The steeper the cup angle, the greater the ability of the bearing to handle thrust loads.

| Product Name: | NSK CZPT CZPT CZPT CZPT Original Brand bearing Tapered Roller Bearing Ball Bearing Wheel Hub Bearing Cylindrical Roller Bearing for Auto Spare Part | ||||

| Size: | 5-600 mm | ||||

| Material: | Grc15 Chrome Steel | ||||

| Lubrication: | Grease Oil | ||||

| Cage: | Steel,Brass, Nylon | ||||

| Roller Type: | Ball, roller | ||||

| Used | machinery,automotive, rolling mill, mining, metallurgical, plastic machinery, Industry | ||||

Detailed Photos

6571 deep groove ball bearings applications :

Industries:

Aerospace, agriculture, automotive, heavy truck, cement, aggregate, coal, oil and gas, construction, gear drives, machine tools, mining, paper, metals, rail and wind.

Benefits:

Enhanced performance in demanding applications.

II. We also produce and supply

Company Profile

Product Parameters

|

TECHNICAL PARAMETERS |

|||

|

Trade Terms: |

FOB |

Service: |

OEM |

|

CIF |

ODM |

||

|

Precision Grade: |

P0(ABEC-1), P6(ABEC3), P5(ABEC5), P4(ABEC-7) P2(ABEC-9) |

Payment Terms: |

Paypal, T/T,L/C, Western Union,alipay, Trade Assurance,and ect. |

|

Taper Roller Bearings Use: |

Taper roller bearings are widely used in automotive, mill, mining, metallurgy, plastics machinery and other industries. |

Shipping: |

By sea, by air, by express delivery |

|

Structure: |

Single row/ Double row / Four row |

||

|

Website: |

chikbearing |

||

| 60 Series Deep Groove Ball bearings Technical Paramrter | |||||

| Bearing NO. | d/mm | D/mm | B/mm | Bearing NO. | |

| d | D | B | rsmin | ||

| 604 | 4 | 12 | 4 | 0.2 | 604 |

| 605 | 5 | 14 | 5 | 0.2 | 605 |

| 606 | 6 | 17 | 6 | 0.3 | 606 |

| 607 | 7 | 19 | 6 | 0.3 | 607 |

| 608 | 8 | 22 | 7 | 0.3 | 608 |

| 609 | 9 | 24 | 7 | 0.3 | 609 |

| 6000 | 10 | 26 | 8 | 0.3 | 6000 |

| 6001 | 12 | 28 | 8 | 0.3 | 6001 |

| 6002 | 15 | 32 | 9 | 0.3 | 6002 |

| 6003 | 17 | 35 | 10 | 0.3 | 6003 |

| 6004 | 20 | 42 | 12 | 0.6 | 6004 |

| 60/22 | 22 | 44 | 12 | 0.6 | 60/22 |

| 6005 | 25 | 47 | 12 | 0.6 | 6005 |

| 60/28 | 28 | 52 | 12 | 0.6 | 60/28 |

| 6006 | 30 | 55 | 13 | 1 | 6006 |

| 60/32 | 32 | 58 | 13 | 1 | 60/32 |

| 6007 | 35 | 62 | 14 | 1 | 6007 |

| 6008 | 40 | 68 | 15 | 1 | 6008 |

| 6009 | 45 | 75 | 16 | 1 | 6009 |

| 6571 | 50 | 80 | 16 | 1 | 6571 |

| 6011 | 55 | 90 | 18 | 1.1 | 6011 |

| 6012 | 60 | 95 | 18 | 1.1 | 6012 |

| 6013 | 65 | 100 | 18 | 1.1 | 6013 |

| 6014 | 70 | 110 | 20 | 1.1 | 6014 |

| 6015 | 75 | 115 | 20 | 1.1 | 6015 |

| 6016 | 80 | 125 | 22 | 1.1 | 6016 |

| 6017 | 85 | 130 | 22 | 1.1 | 6017 |

| 6018 | 90 | 140 | 24 | 1.5 | 6018 |

| 6019 | 95 | 145 | 24 | 1.5 | 6019 |

| 6571 | 100 | 150 | 24 | 1.5 | 6571 |

| 6571 | 105 | 160 | 26 | 2 | 6571 |

| 6571 | 110 | 170 | 28 | 2 | 6571 |

| 6571 | 120 | 180 | 28 | 2 | 6571 |

| 6026 | 130 | 200 | 33 | 2 | 6026 |

| 6571 | 140 | 210 | 33 | 2 | 6571 |

| 6030 | 150 | 225 | 35 | 2.1 | 6030 |

| 6032 | 160 | 240 | 38 | 2.1 | 6032 |

| 6034 | 170 | 260 | 42 | 2.1 | 6034 |

| 6036 | 180 | 280 | 46 | 2.1 | 6036 |

| 6038 | 190 | 290 | 46 | 2.1 | 6038 |

| 6040 | 200 | 310 | 51 | 2.1 | 6040 |

| 6044 | 220 | 340 | 56 | 3 | 6044 |

| 6048 | 240 | 360 | 56 | 3 | 6048 |

| 6052 | 260 | 400 | 65 | 4 | 6052 |

| 6056 | 280 | 420 | 65 | 4 | 6056 |

| 6060 | 300 | 460 | 74 | 4 | 6060 |

| 6064 | 320 | 480 | 74 | 4 | 6064 |

| 6068 | 340 | 520 | 82 | 5 | 6068 |

| 6072 | 360 | 540 | 82 | 5 | 6072 |

| 6076 | 380 | 560 | 82 | 5 | 6076 |

| 6080 | 400 | 600 | 90 | 5 | 6080 |

| 6084 | 420 | 620 | 90 | 5 | 6084 |

| 6088 | 440 | 650 | 94 | 6 | 6088 |

| 6092 | 460 | 680 | 100 | 6 | 6092 |

| 6096 | 480 | 700 | 100 | 6 | 6096 |

| 60/500 | 500 | 720 | 100 | 6 | 60/500 |

| 62 Series Deep Groove Ball bearings Technical Paramrter | |||||

| Bearing NO. | Bearing NO. | ||||

| d | D | B | rsmin | ||

| 623 | 3 | 10 | 4 | 0.15 | 623 |

| 624 | 4 | 13 | 5 | 0.2 | 624 |

| 625 | 5 | 16 | 5 | 0.3 | 625 |

| 626 | 6 | 19 | 6 | 0.3 | 626 |

| 627 | 7 | 22 | 7 | 0.3 | 627 |

| 628 | 8 | 24 | 8 | 0.3 | 628 |

| 629 | 9 | 26 | 8 | 0.3 | 629 |

| 6200 | 10 | 30 | 9 | 0.6 | 6200 |

| 6201 | 12 | 32 | 10 | 0.6 | 6201 |

| 6202 | 15 | 35 | 11 | 0.6 | 6202 |

| 6203 | 17 | 40 | 12 | 0.6 | 6203 |

| 6204 | 20 | 47 | 14 | 1 | 6204 |

| 62/22 | 22 | 50 | 14 | 1 | 62/22 |

| 6205 | 25 | 52 | 15 | 1 | 6205 |

| 62/28 | 28 | 58 | 16 | 1 | 62/28 |

| 6206 | 30 | 62 | 16 | 1 | 6206 |

| 62/32 | 32 | 65 | 17 | 1 | 62/32 |

| 6207 | 35 | 72 | 17 | 1.1 | 6207 |

| 6208 | 40 | 80 | 18 | 1.1 | 6208 |

| 6209 | 45 | 85 | 19 | 1.1 | 6209 |

| 6210 | 50 | 90 | 20 | 1.1 | 6210 |

| 6211 | 55 | 100 | 21 | 1.5 | 6211 |

| 6212 | 60 | 110 | 22 | 1.5 | 6212 |

| 6213 | 65 | 120 | 23 | 1.5 | 6213 |

| 6214 | 70 | 125 | 24 | 1.5 | 6214 |

| 6215 | 75 | 130 | 25 | 1.5 | 6215 |

| 6216 | 80 | 140 | 26 | 2 | 6216 |

| 6217 | 85 | 150 | 28 | 2 | 6217 |

| 6218 | 90 | 160 | 30 | 2 | 6218 |

| 6219 | 95 | 170 | 32 | 2.1 | 6219 |

| 6220 | 100 | 180 | 34 | 2.1 | 6220 |

| 6221 | 105 | 190 | 36 | 2.1 | 6221 |

| 6222 | 110 | 200 | 38 | 2.1 | 6222 |

| 6224 | 120 | 215 | 40 | 2.1 | 6224 |

| 6226 | 130 | 230 | 40 | 3 | 6226 |

| 6228 | 140 | 250 | 42 | 3 | 6228 |

| 6230 | 150 | 270 | 45 | 3 | 6230 |

| 6232 | 160 | 290 | 48 | 3 | 6232 |

| 6234 | 170 | 310 | 52 | 4 | 6234 |

| 6236 | 180 | 320 | 52 | 4 | 6236 |

| 6238 | 190 | 340 | 55 | 4 | 6238 |

| 6240 | 200 | 360 | 58 | 4 | 6240 |

| 6244 | 220 | 400 | 65 | 4 | 6244 |

| 6248 | 240 | 440 | 72 | 4 | 6248 |

| 6252 | 260 | 480 | 80 | 5 | 6252 |

| 63 Series Deep Groove Ball bearings Technical Paramrter | |||||

| Bearing NO. | Bearing NO. | ||||

| d | D | B | rsmin | ||

| 633 | 3 | 13 | 5 | 0.2 | 633 |

| 634 | 4 | 16 | 5 | 0.3 | 634 |

| 635 | 5 | 19 | 6 | 0.3 | 635 |

| 6300 | 10 | 35 | 11 | 0.6 | 6300 |

| 6301 | 12 | 37 | 12 | 1 | 6301 |

| 6302 | 15 | 42 | 13 | 1 | 6302 |

| 6303 | 17 | 47 | 14 | 1 | 6303 |

| 6304 | 20 | 52 | 15 | 1.1 | 6304 |

| 63/22 | 22 | 56 | 16 | 1.1 | 63/22 |

| 6305 | 25 | 62 | 17 | 1.1 | 6305 |

| 63/28 | 28 | 68 | 18 | 1.1 | 63/28 |

| 6306 | 30 | 72 | 19 | 1.1 | 6306 |

| 63/32 | 32 | 75 | 20 | 1.1 | 63/32 |

| 6307 | 35 | 80 | 21 | 1.5 | 6307 |

| 6308 | 40 | 90 | 23 | 1.5 | 6308 |

| 6309 | 45 | 100 | 25 | 1.5 | 6309 |

| 6310 | 50 | 110 | 27 | 2 | 6310 |

| 6311 | 55 | 120 | 29 | 2 | 6311 |

| 6312 | 60 | 130 | 31 | 2.1 | 6312 |

| 6313 | 65 | 140 | 33 | 2.1 | 6313 |

| 6314 | 70 | 150 | 35 | 2.1 | 6314 |

| 6315 | 75 | 160 | 37 | 2.1 | 6315 |

| 6316 | 80 | 170 | 39 | 2.1 | 6316 |

| 6317 | 85 | 180 | 41 | 3 | 6317 |

| 6318 | 90 | 190 | 43 | 3 | 6318 |

| 6319 | 95 | 200 | 45 | 3 | 6319 |

| 6320 | 100 | 215 | 47 | 3 | 6320 |

| 6321 | 105 | 225 | 49 | 3 | 6321 |

| 6322 | 110 | 240 | 50 | 3 | 6322 |

| 6324 | 120 | 260 | 55 | 3 | 6324 |

| 6326 | 130 | 280 | 58 | 4 | 6326 |

| 6328 | 140 | 300 | 62 | 4 | 6328 |

| 6330 | 150 | 320 | 65 | 4 | 6330 |

| 6332 | 160 | 340 | 68 | 4 | 6332 |

| 6334 | 170 | 360 | 72 | 4 | 6334 |

Packaging & Shipping

| After-sales Service: | 24 Hours Service Online |

|---|---|

| Warranty: | 12 Month |

| Type: | Deep Groove Ball Bearing |

| Material: | Gcr15 Bearing Steel |

| Tolerance: | P0 P6 |

| Certification: | ISO9001 |

| Samples: |

US$ 0.01/Set

1 Set(Min.Order) | |

|---|

Materials Used in Bearings

If you’re not familiar with the types of bearings, you may be interested in knowing more about the materials used to manufacture them. Here’s a look at what each type of bearing is made of, how it’s used, and how much they cost. To find the right bearing for your application, it’s important to choose a quality lubricant. The materials used in bearings are determined by their type and applications. Choosing the right lubricant will extend its life, and protect your machine’s parts from damage and premature wear.

Materials used in bearings

Bearings are made from a variety of materials. Stainless steel is a common material used for the components of bearings. It has a higher content of chromium and nickel. When exposed to oxygen, chromium reacts with it to form chromium oxide, which provides a passive film. For higher temperatures, teflon and Viton are also used. These materials offer excellent corrosion resistance and are often preferred by manufacturers for their unique properties.

Stainless steel is another material used in bearings. AISI 440C is a high-carbon stainless steel commonly used in rolling-contact bearings. It is widely used in corrosive environments, especially in applications where corrosion resistance is more important than load capacity. It can also be heat-treated and hardened to 60 HRC, but has lower fatigue life than SAE 52100. Stainless steel bearings may carry a 20-40% price premium, but their superior performance is worth the extra money.

Graphite and molybdenum disulfide are two of the most common materials used in bearings. While graphite is a popular material in bearings, it has very poor corrosion resistance and is unsuitable for applications where oil or grease is required. Graphite-based composite materials are another option. They combine the benefits of both graphite and ceramic materials. A variety of proprietary materials have been developed for high-temperature use, such as graphite and MoS2.

Wood bearings have been around for centuries. The oldest ones used wood and Lignum Vitae. These materials were lightweight, but they were incredibly strong and durable. Wood bearings were also lubricated with animal fats. During the 1700s, iron bearings were a popular choice. In 1839, Isaac Babbitt invented an alloy containing hard metal crystals suspended in a softer metal. It is considered a metal matrix composite.

Applications of bearings

Bearings are used in many different industries and systems to help facilitate rotation. The metal surfaces in the bearings support the weight of the load, which drives the rotation of the unit. Not all loads apply the same amount of force to bearings, however. Thrust and radial loads act in distinctly different ways. To better understand the different uses of bearings, let’s examine the various types of bearings. These versatile devices are essential for many industries, from automobiles to ships and from construction to industrial processes.

Cylindrical roller bearings are designed to support heavy loads. Their cylindrical rolling element distributes the load over a larger area. They are not, however, suited to handling thrust loads. Needle bearings, on the other hand, use small diameter cylinders and can fit into tighter spaces. The advantages of these types of bearings are numerous, and many leading producers are now leveraging the Industrial Internet of Things (IIoT) to develop connected smart bearings.

As a power generation industry, bearings play an essential role. From turbines to compressors, from generators to pumps, bearings are essential components of equipment. In addition to bearings, these components help move the equipment, so they can work properly. Typically, these components use ball bearings, although some roller bearings are used as well. In addition to being efficient and durable, these types of bearings also tend to be built to meet stringent internal clearance requirements and cage design requirements.

In addition to bearings for linear motion, bearings can also bear the weight of a rotary part. Depending on the application, they can be designed to minimize friction between moving parts. By constraining relative motion, bearings are used to reduce friction within a given application. The best-designed bearings minimize friction in a given application. If you’re in the market for a new bearing, NRB Industrial Bearings Limited is an excellent source to begin your search.

Types of bearings

The type of bearings you choose will have a significant impact on the performance of your machinery. Using the right bearings can increase efficiency, accuracy, and service intervals, and even reduce the cost of purchasing and operating machinery. There are several different types of bearings to choose from, including ball bearings and flexure bearings. Some types use a fluid to lubricate their surfaces, while others do not.

Plain bearings are the most common type of bearing, and are used for a variety of applications. Their cylindrical design allows for a relatively smooth movement. Often made of copper or other copper alloy, they have low coefficients of friction and are commonly used in the construction industry. Some types of plain bearings are also available with a gudgeon pin, which connects a piston to a connecting rod in a diesel engine.

Magnetic bearings are the newest type of bearing. They use permanent magnets to create a magnetic field around the shaft without requiring any power. These are difficult to design, and are still in the early stages of development. Electromagnets, on the other hand, require no power but can perform very high-precision positioning. They can be extremely durable and have a long service life. They are also lightweight and easy to repair.

Another type of bearing is needle roller. These are made of thin, long, and slender cylinders that are used in a variety of applications. Their slender size is ideal for a space-constrained application, and their small profile allows them to fit in tight places. These types of bearings are often used in automotive applications, bar stools, and camera panning devices. They have several advantages over ball bearings, including the ability to handle heavy axial loads.

Cost of bearings

A wide range of factors affect the cost of aerospace bearings, including the bearing material and its volatility. Manufacturers typically use high-grade steel for aircraft bearings, which are highly affected by fluctuations in the steel price. Government policies also play a part in the variation in trade price. The implementation of COVID-19 has changed the market dynamics, creating an uncertain outlook for supply and demand of aerospace bearings. New trade norms and transportation restrictions are expected to hamper the growth of this industry.

Demand for aerospace bearings is largely driven by aircraft manufacturers. In North America, aircraft manufacturers must meet extremely high standards of weight, performance, and quality. They also must be lightweight and cost-effective. This has resulted in a rising cost of aerospace bearings. The market for aerospace bearings is expected to grow at the highest CAGR over the next few years, driven by increasing investments in defense and aerospace infrastructure across Asia-Pacific.

Hub assemblies are also expensive. A wheel hub will cost between $400 and $500 for one set of bearings. In addition to this, the speed sensor will be included. The average cost of wheel bearings is between $400 and $500 for one side, including labor. But this price range is much lower if the bearing is a replacement of an entire wheel assembly. It is still worth noting that wheel hub bearings can be purchased separately for a lower price.

Replacement of one or two wheel bearings will depend on the model and year of the vehicle. For a small car, one rear wheel bearing can cost between $190 and $225, whereas two front wheel hubs can cost upwards of $1,000. Labor and parts prices will vary by location, and labor costs may also be covered under some warranty plans. If you decide to have it done yourself, be sure to ask multiple shops for estimates.

Inspection of bearings

To maintain bearing performance and prevent accidents, periodic inspections are essential. In addition to ensuring reliability, these inspections improve productivity and efficiency. Regular maintenance includes disassembly inspection, replenishment of lubricant and monitoring operation status. Here are some common ways to perform the necessary inspections. Keep reading to learn how to maintain bearings. After disassembly, you must clean the components thoroughly. Ensure that the bearings are free of burrs, debris, and corrosion.

Ultrasound technology is an excellent tool for monitoring slow-speed bearings. Most ultrasound instruments offer wide-ranging sensitivity and frequency tuning. Ultrasound can also be used to monitor bearing sound. Ultra-slow bearings are usually large and greased with high-viscosity lubricant. Crackling sounds indicate deformity. You can also listen for abnormal noise by plugging a vibration analyzer into the machine. Once the machine shows abnormal noise, schedule additional inspections.

Ultrasonic inspection involves using an ultrasound transducer to measure the amplitude of sound from a bearing. It is effective in early warnings of bearing failure and prevents over-lubrication. Ultrasound inspection of bearings is a cost-effective solution for early diagnosis of bearing problems. In addition to being a reliable tool, ultrasonic testing is digital and easy to implement. The following are some of the advantages of ultrasonic bearing inspection.

Dynamic quality evaluation involves the use of a special fixture for measuring bearing deformations under low shaft speed and light radial load. The size of the fixture influences the value of the deformations. A fixture should be sized between the diameter of the sensor and the roller to ensure maximum precision. The outer deformation signal is more sensitive with a larger sensor diameter. A vibration-acceleration sensor is used for the contrast test.

editor by CX 2023-06-13

China Other Bearings 6001 6004 6201 6202 6203 6204 6205 6207 6300 6301 2RS 6302 6305 Bearing Deep Groove Ball Bearing carrier bearing

Sort: BALL

Structure: Deep Groove

Applicable Industries: Hotels, Garment Retailers, Developing Material Shops, Producing Plant, Machinery Fix Outlets, Foods & Beverage Manufacturing unit, Farms, Restaurant, Property Use, Retail, Foods Shop, Printing Stores, Development works , Power & Mining, Food & Beverage Retailers, Other, Advertising and marketing Firm

Bore Dimensions: 12 – twelve.1 mm

Design Amount: 6201

Precision Ranking: P0 P6 P5 P4 P2

Seals Kind: open up Z ZZ RS 2RS

Amount of Row: Solitary row

Material: Bearing metal, stainless metal, ceramic

Package deal: Tube,Carton

Sample: Appropriate

weight: .04kg

Software: Equipment

Cage: Steel Cage.copper Cage.nylon Cage

Services: OEM Custom-made Services

Function: Lengthy Existence Substantial Speed

MOQ: 1

Shipping Time: 1-3 Days

Packaging Information: Plastic Bag, All types of Cylindrical Roller Bearing N 224M 12571540mm Craft Paper Bag,Tube,Carton,Wooden Circumstance,Pallet and many others.forturbo ball bearing 6002rs ball bearing with ball bearing value listing

Port: HangZhou Port

Goods Description Deep groove ball bearing Fundamental parametersThese Bearings are developed for radial, axial, and also CZPT load purposes. Deep Groove Ball Bearings offer·Uni or bi-directional load carrying capability·Very high-pace rotation·Very good managing accuracy·Low sounds and low friction torque

| product identify | Deep groove Ball Bearing 6201 |

| MOQ | 1 |

| Delivery time | 1-3 days |

| Number of rows | single row |

| Service | Optional grease and sealOEM Custom-made Providers |

| Uses of self-aligning ball bearings | Deep groove ball bearings can be utilised in gearboxes, instruments, motors, household appliances, inside combustion engines,transportation autos, agricultural equipment, construction machinery, design equipment, roller roller skates, Tractor PTO electrical power air blast agriculture sprayer yo-yo, and so on. |

| Minature ball bearing | 604–608 609623–629634–639694–699684–689 | ||||||

| Deep groove ball bearing | 6000 sereis6200 series6300 series6700 series6800 series6900 series16000 series and width bearings | ||||||

| Inch bearing | 1601–1658R2-R24 | ||||||

| MR Series | |||||||

| Flange bearings | |||||||

What is the purpose of the bushing?

If you notice the truck making noises when cornering, the bushings may be worn. You may need to replace the ball joint or stabilizer bar, but a simple inspection will reveal that the noise is coming from the bushing. The noise from a worn bushing on a metal joint can mimic the sound of other problems in the suspension, such as a loose stabilizer bar or a failed ball joint.

Function

What is the purpose of the bushing? They play an important role in the operation of various mechanical parts. Their main functions include reducing the clearance between the shaft and the bearing and reducing the leakage of the valve. Bushings are used in different ways to ensure smooth operation and longevity. However, some new designers don’t appreciate the functionality of the case. So let’s discuss these features. Some of their most common applications are listed below.

First, the shell does a lot of things. They reduce noise, control vibration, and provide amazing protection for all kinds of industrial equipment. Large industrial equipment faces more wear, vibration and noise, which can render it completely inoperable. Bushings help prevent this by reducing noise and vibration. Bushing sets also extend equipment life and improve its performance. Therefore, you should not underestimate the importance of the casing in your device.

Another common function of bushings is to support components during assembly. In other words, the bushing reduces the risk of machine wear. In addition to this, they are superior to bearings, which are notoriously expensive to maintain. However, they are still useful, and their versatility cannot be overemphasized. If you’re considering installing one, you’ll be glad you did! These products have become a necessity in the modern industrial world. If you’re wondering how to choose one, here are some of the most common bushing uses.

Electrical bushings are an important part of many electrical equipment. They carry high voltage currents through the enclosure and provide an insulating barrier between live conductors and metal bodies at ground potential. They are made of a central conductive rod (usually copper or aluminum) and surrounding insulators made of composite resin silicone rubber. Additionally, the bushings are made of various materials. Whether copper, aluminum or plastic, they are an important part of many types of electrical equipment.

type

There are several different types of bushings on the market today. They may be cheap but they are of good quality. These products can be used in telephones, cable television, computer data lines and alarm systems. The key to buying these products online is finding the right appliance store and choosing a high-quality product. An online appliance store should have comprehensive information and ease of use. For the right electrical bushing, you should look for reliable online stores with the best prices and high quality products.

Capacitive grading bushings use conductive foils inserted into paper to stabilize the electric field and balance the internal energy of the bushing. The conductive foil acts as a capacitive element, connecting the high voltage conductor to ground. These types of bushings are sometimes referred to as capacitor grade bushings. Capacitive grading bushings are usually made of paper impregnated with epoxy resin or mineral oil.

When buying enclosures, you should know how they are used. Unlike ball bearings, bushings should be stored upright so that they are in the correct working position. This is because horizontal placement can cause air bubbles to form in the fill insulation. It is also important to store the bushing properly to prevent damage. The wrong way to store these components can result in costly repairs.

In addition to the physical structure, the bushing insulation must also be effective over the long term. It must resist partial discharge and working electric field stress. The material and design of the bushing can vary widely. Early on, porcelain-based materials were popular in bushing designs. Porcelain was chosen because of its low cost of production and very low linear expansion. Ceramic bushings, on the other hand, require a lot of metal fittings and flexible seals.

Durability

The RIG 3 Bushing Durability Test Standard simulates real-world service conditions for automotive bushings. This three-channel test standard varies casing loads and stresses by applying a range of different load conditions and various control factors. This test is critical to the durability of the case, as it accurately reproduces the dynamic loads that occur during normal use. This test is a key component of the automotive industry and is widely used in many industries.

The Advanced Casing Model has five modules to address asymmetry, nonlinearity, and hysteresis. This model also represents the CZPT lag model. The model can be parameterized in the time domain using MATLAB, and the results can be exported to other simulation software. The developed bushing model is a key component in the durability and performance of vehicle suspension components.

A conductive material is coated on the inner surface of the sleeve. The coating is chosen to conduct a certain amount of current. The conductive path extends from the blade spacer 126 to the sleeve projecting edge 204 and then through the housing 62 to the ground. The coating is made of a low friction material and acts as a wear surface against the bushing sidewall 212 and the housing 62 .

Another important factor in a bushing’s durability is its ability to friction. The higher the operating speed, the greater the load on the bushing. Since bushings are designed for lighter loads and slower speeds, they cannot handle large loads at high speeds. The P-max or V-max value of a bushing is its maximum load or speed at 0 rpm. The PV value must be lower than the manufacturer’s PV value.

price

If you need to replace the bushing on the control arm, you should understand the cost involved. This repair can be expensive, depending on the make and model of your car. Generally, you should pay between $105 and $180 for a replacement. However, you can choose to have it done by a mechanic at a lower cost. The labor cost for this job can be around $160, depending on your automaker.

The cost of replacing the control arm bushings can range from $200 on the low end to $500 on a luxury car. While parts are cheap, labor costs are the highest. Mechanics had to remove suspension and wheel assemblies to replace bushings. If you have some mechanical knowledge, you can replace the bushing yourself. Control arm bushings on the wheel side are usually about $20 each. Still, if you’re not a mechanic, you can save money by doing it yourself.

Install

Press-fit bushings are installed using a retaining ring with a diameter 0.3/0.4 mm larger than the inner diameter of the bushing. To ensure accurate installation, use a mechanically driven, pneumatic or hydraulic drill and insert the bushing into the appropriate hole. This process is best done using mounting holes with drilled holes for the clamps. Make sure the mounting hole is in the center of the bushing and free of debris.

Once the bushing is positioned, use a vise to install its nut. A cold bushing will compress and fit the shell better. Place the sleeve in the refrigerator for at least 24 hours to aid installation. After removing the bushing from the refrigerator, make sure it has enough diameter to fit into the enclosure. Next, place the opposite socket into the enclosure and use it as a stand. After a few minutes, the bushing should be fully seated in the housing.

Install the new bushing into the housing hole. If the previous one had a metal case, insert the new one through the taper. Always lubricate the inner and outer surfaces of the bushing. Then, apply pressure to the inner metal sleeve of the new bushing. You may notice that the new bushing does not exactly match the housing hole. However, that’s okay because the outer diameter of the bushing is larger than the outer diameter of the hub drive.

The installation of the bushing requires the use of the hydraulic unit 16 . Hydraulic unit 16 is located near the #1 journal of the camshaft and extends from #2 to #7. Hydraulic fluid forces piston 22 away from the outer end of cylinder 20 and pushes shaft 14 forward. The shaft is then moved forward, pushing the bushing 17 onto the piston. Multiple bushings can be installed in a single engine.

editor by czh 2023-02-20

China HXHV 6011 6025 6029 6085 6100 6102 6112 6180 6210 6212 6318 6326 6509 6603 6605 6205 6413 RZ 2RS 6202ZZ Deep Groove Ball Bearing bearing distributors

Kind: BALL

Composition: Deep Groove

Applicable Industries: Building Content Stores, Printing Outlets, Farms, Design works , Garment Outlets, Cafe, Advertising and marketing Firm, Equipment Repair Shops, Foods & Beverage Shops, Foodstuff Store, Retail, Power & Mining, Production Plant, Foods & Beverage Manufacturing facility, Resorts, Residence Use

Bore Size: ten – 60

Product Number: 6011

Precision Score: P6

Seals Type: ZZ 2RS Open up

Number of Row: Single row

Substance: Ceramic ball

Cage: Metal Cage.Brass Cage.Gcr15

Software: Toys and adornment

Certificate: ISO9001:2000

Lubrication: Oil

Support: OEM Services.Design Provider

Vibration: Z1V1 Z2V2 Z3V3 Z4V4

Cage material: Gcr15.stainless Metal

Size: 55x90x18mm

Excess weight: .362kgs

Packaging Particulars: 6413 RZ 2RS 6202ZZ Deep Groove Ball BearingA: tube deal 6413 RZ 2RS 6202ZZ Deep Groove Ball Bearing

6413 RZ 2RS 6202ZZ Deep Groove Ball Bearing

| Goods name | 6413 RZ 2RS 6202ZZ Deep Groove Ball Bearing | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model identify | HXHV or OEM | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sequence | 6011 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Content | Stainless steel or Gcr15 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Good quality standard | ISO9001, ABEC-1(Z1V1) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Service | Original support | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Tolerance Grades | ABEC-1 (P0), ABEC-3 (P6), HanBuild 80SS75 2.39N.m 5.0A 3000-6000rpm automated feeder 220V ASD275 servo driver kit 80 integrated 750w ac servo motor ABEC-5(P5) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sounds Stage | EMQ V1 Z2, EMQ V2 Z3, EMQ V3 Z4, EMQ V4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sealing/Shield | Open up, Z, ZZ,RS, 2RS,RZ,2RZ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Benefit | A:bearing moves quite Fast & Quiet, with really sleek hand sensation B:Higher precision, prolonged existence, reduced noiseC:higher-end technological innovation D:great aftersales support | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bundle | A: tube package deal QQ:2397548557

Packing & Shipping and delivery Packing:

Types of Ball BearingsModern ball bearing configurations have different materials and geometries to meet the demands of different working environments and applications. There are different types of ball bearings: single row deep groove, double-row deep groove, angular contact ball bearing, thrust, and self-aligning. Let us look at the differences between each type and learn why they are important for various purposes. Listed below are some of the most common types of ball bearings. Miniature bearingsAlthough miniature ball bearings are a popular choice for small mechanical components, they are not without their challenges. They must be properly lubricated and stored in clean rooms. A strand of hair could ruin a miniature bearing. Fortunately, manufacturers offer lubrication services and a “Clean Room” for customers to store their miniature bearings safely. Read on to learn more about these small bearings and how they can help you. Self-aligning ball bearings

Ceramic ball bearingsCeramic ball bearings have several advantages over steel or metal bearings. These include increased acceleration capability, reduced friction, improved wear-resistance, and higher speeds. The United States holds the leading position in the global ceramic ball bearings market thanks to a rebounding motor vehicle production and healthy fixed investment environment. In the United States, there are three primary markets for ceramic ball bearings: healthcare, automotive, and aerospace. Here are the main benefits of ceramic ball bearings: Steel carbon ball bearingsHigh precision G25 ball bearings are made of the highest grade chrome steel and hot forged from bar stock. Statistical process control and exacting atmospheres help ensure uniform hardness and microstructure. Moreover, these bearings are of the highest quality, with fine surface finish and a tight tolerance. This makes them the most widely used and reliable choice for industrial and automotive applications. However, there are some considerations that should be taken into account before acquiring a steel carbon ball bearing. Stainless steel ball bearings

Stainless steelStainless steel ball bearings can be used in various applications. Besides being corrosion resistant, they also last longer thanks to the Molded-Oil lubrication technology. Stainless steel ball bearings are clean units, which saves time and money in terms of maintenance, replacement, and downtime. But what are the advantages of stainless steel ball bearings? Let us discuss these benefits. Also, we’ll discuss their advantages and disadvantages. Plastic ball bearings

China motorcycle bearings 6004 6301 6203 wheel bearing 6205 motor bearing bearing assemblyMerchandise Description

Radial ball bearing 6301RS bicycle bearings Rodamiento 6301 roller bearing/car bearings

one.Bearing Manufacturing unit much more than twenty years The kind of fudabearings ,element resources used will decide the existence span, trustworthiness and performance of the bearings. Nevertheless, there are several variables impacting the functionality of the bearings which contain the variety of the load carrying capability, the rolling contact circumstances, and the cleanliness of the running atmosphere and the dimensional stability of the bearing elements. Fuda bearing business has adopted the carbon-chromium steel materials(Gcr15) in our productionof the bearing.

Packaging & Shipping for Radial ball bearing 6301RS bicycle bearings Rodamiento 6301 roller bearing/automobile bearings

One particular of the top bearing producers and exporters in China

China CZPT Bearing Company was recognized in 1996 and is 1 of the foremost bearing manufacturers and exporters in China. CZPT specializes in the layout and generation of substantial high quality, large precision deep groove ball bearings and pillow block bearings. At present, the Corporation has a lot more than 1,000 employees, a fixed belongings of 1.05 billion yuan, and produces 250 million sets of bearings each year. In 2571, the Corporation attained bearing income of 650 million yuan. The Corporation’s products are widely utilized in far more than fifty international locations and regions below 2 independent manufacturers, particularly “F&D” and “CBB”.

Analysis and Growth

Considering that 2008, the Corporation has set up a Research & Development Centre equipped with numerous laboratories employed for precision measurement, mechanical testing, lifespan testing, and physicochemical tests, to repeatedly update its expertise and raise its production standard and product’s precision. Our workshops are mounted with a series of superior numerically-controlled, grinding and assembly tools that use centralized filtration and cooling systems. Together with the production tools suppliers, we developed these grinding, extremely-precision, fully automatic integrated creation traces, and possess the mental house legal rights. The precision level of the products are at P5 stage and previously mentioned, with sound degree CZPT Z4, V4 and previously mentioned. Some of our initiatives have exceeded the thirty% precision reserves. Our products are commonly employed in electrical motors, cars, bikes, house appliances, textile, electric equipment and water pump tools industries, each locally and globally.

Why Pick US About US Fuda Bearing Corporation Co., Ltd. was founded in 1996, and turned 1 of Chinese largest bearing companies and exporters. which specializes in designing and generating deep groove ball bearings, pillow block bearings with substantial high quality & precision. Following far more than ten years’hard operate, CZPT has produced into a high-tech company that is capable of bearing study & development, manufacturing, and advertising and marketing. The Corporation is made up of 5 subsidiaries such as ZHangZhoug CZPT Bearing Co., Ltd, Flate Precision Tech. Co.,Ltd, HangZhou Unit Equipment Co., Ltd, HangZhou Oyat Bearing Co.,Ltd, CZPT Bearing Corporation Imp.& Exp.Co.Ltd. Now CZPT has workers far more than 1000 with the mounted assets of RMB 1.05 billion. And the annual generation ability can achieve 25 million sets. In 2571, the bearing sales quantity was RMB 650 hundreds of thousands.In addition to it creates 2 self-owned brand names referred to as F&D and CBB. The merchandise are properly received in more than fifty nations around the world and areas.

Top quality Assurance

Our Support Thanks really significantly to overview F&D ball bearing Radial ball bearing 6301RS bicycle bearings Rodamiento 6301 roller bearing/car bearings.

###

###

###

###

###

###

###

###

###

###

###

###